Talk or write to our specialist to find the right solution for your lightweight concrete production.

- Project: production of homogeneous EPS self-insulation concrete blocks

- Time: contract signed on 15th October 2021, project started in May 2022

- Location: Bozhou, Xinjiang, China

- Production output: 300-400m³ per day

Project outcome: installation and commissioning took one month, with technical training completed in one week. Initial production exceeded 200m³ per day, reaching the target output within one week. The cutting accuracy met expectations, and the customer was satisfied.

- Project: production of EPS foamed concrete blocks

- Time: 5th April 2023

- Location: Aksu, Xinjiang, China

- Production output: 800m³ per day

Project outcome: The client utilized local mountain sand resources and provided their own facilities for sand crushing, ball milling, slurry storage, and measuring and conveying facilities. Installation was completed in two months, with commissioning and production training taking 20 days. The target output was achieved, and the products passed inspections, obtaining government certification.

- Project: production of homogeneous self-insulation concrete blocks

- Time: 12th March 2022

- Location: Aral, Xinjiang, China

- Production output: 500m³ per day

Project outcome: the production line adopted an environmentally friendly waste recycling process, utilizing stone powder resources to achieve resource recycling and reduce production costs. After the company's technical trainers completed the training, they were hired by the client for an extended period. The client was very satisfied with the equipment and product quality, reaching the production capacity of 500m³ per day with an annual output of 150,000m³.

- Project: production of EPS foamed concrete blocks

(The client invested in a medium-sized production line for uniform self-insulating concrete blocks to meet local market demand and their sales goals.) - Time: 12th June 2022

- Location: Wensu Town, Aksu, Xinjiang, China

- Production output: 300-400m³ per day

Project outcome: Before signing the contract, the client visited other customers in different regions and highly recognized our equipment. After the smooth commissioning, the client gave high praise for our after-sales service. The client's homogeneous self-insulation blocks sold well in the local market, with increasing orders.

- Project: production of homogeneous EPS self-insulation concrete blocks

- Time: 22th March 2022

- Location: Lop County, Hotan, Xinjiang, China

- Production output: 500m³ per day

Project outcome: Hengde optimized the equipment's process parameters, block sizes, and performance indicators based on the characteristics of local raw materials and market demand. The client was one of the earliest in the southern Xinjiang region to start production, and other regional clients visited their site. The equipment operated stably, maintaining consistent production and quality.

- Project: production of EPS self-insulation concrete blocks

- Time: 28th June 2022

- Location: Yarkant County, Kashgar, Xinjiang, China

- Production output: 300m³ per day

Project outcome: Hengde provided customized homogeneous self-insulation block production equipment and project investment planning based on the client's actual needs and investment budget. During the training period, the client and our technical personnel cooperated well, leading to early production. The client expressed high satisfaction with the equipment and products, agreeing to support our promotional efforts in the Xinjiang region.

- Project: optimization and upgrading of EPS self-insulation concrete block production line

- Time: 16th July 2023

- Location: Korla, Bayingol, Xinjiang, China

- Production output: 100m³ per day

Project outcome: This small self-insulation block production factory previously used reciprocating saw cutting, which was semi-automatic, had low output, large dimensional errors, and uneven product appearance. Hengde provided a new rotary mold cutting machine, solving these issues and receiving high praise from the client.

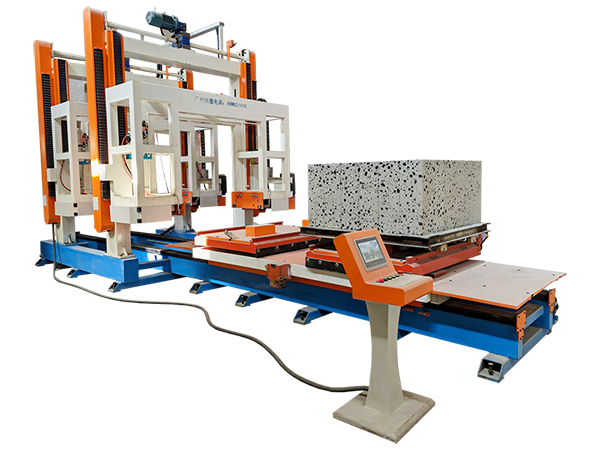

- Project: optimization and upgrading of homogeneous EPS self-insulation concrete block production line by replacing reciprocating saw cutter with high precision three-head gantry vertical cutter

- Time: 12th April 2023

- Location: Pishan County, Hotan, Xinjiang, China

- Production output: 300m³ per day

The client initially purchased a production line from another company, which used reciprocating saws, resulting in large dimensional errors, low cutting efficiency, low production capacity, and uneven surfaces. These issues led to poor product sales and contractor complaints. The client then sought help from Hengde and purchased two sets of three-head CNC cutting machines. This upgrade achieved:

- A threefold increase in production capacity with high-precision cutting.

- Product dimensional errors reduced to ≤1mm, with smooth surfaces and low cutting losses.

- With the same manpower and time, production capacity increased threefold, reducing production costs. The client plans to expand the production line and purchase our entire production line.

- Project: plant retrofitting by modifying autoclaved aerated concrete (AAC) block production line into EPS self-insulation concrete block production line

- Time: 22th December 2021

- Location: Tumxuk, Kashgar, Xinjiang, China

- Production output: 200m³ per day

Project outcome: Hengde formulated a configuration list and production line installation layout based on the client's output needs. During training, Hengde's technical team effectively communicated with the client's team. With the client's AAC production technology knowledge, the training on self-insulation block processes was quick and smooth. One year after production, the client reported stable equipment operation and significantly lower production costs than the industry average, enhancing the client's market competitiveness.

- Project: modification of autoclaved aerated concrete (AAC) block production line into EPS self-insulation concrete block production line by upgrading equipment including concrete mixing machine, concrete block cutter, concrete clamp lifting and stacking machine, etc., to improving automation level and production efficiency.

- Time: 13th May 2023

- Location: Hejing County, Korla, Bayingol, Xinjiang, China

- Production output: 300m³ per day

Project outcome: The client added a specialized mixer for self-insulation blocks, a pre-cutter, cutting line, and a pallet-free packaging line to the original production line. After the training was completed, the client was satisfied and agreed to support visits from other potential customers.

- Project: Production of EPS foamed concrete wall panels

- Time: 26th August 2024

- Location: Anyang, Henan, China

- Production output: 80-100m³ per day

A customer from Nanyang, Henan, which is well-known for being a hub of building materials and machinery, recently sought our assistance despite having local options available. After comparing multiple factories and lightweight wall panel equipment, the customer found that the local equipment lacked in terms of precision, automation, and durability. They expressed that the production line we offered, with its efficient design and advanced features, matched their expectations. Following a live demonstration of our production capabilities, the customer chose to collaborate with us, confident in the reliability of our equipment.

- Project: Production of EPS foamed concrete blocks

- Time: 7th May 2024

- Location: Wuhan, Hubei, China

- Production output: 150m³ per day

A customer from Hubei recently had great success after implementing our self-insulating block production equipment. Initially, they had opted for a cheaper production line, which unfortunately failed to operate efficiently, leading to a year of wasted time and significant operational costs. We stepped in and provided an upgrade and transformation plan for their equipment, allowing them to achieve smooth and stable daily production. The customer’s output now consistently meets the high demand in their local market. They expressed satisfaction with both our equipment and the after-sales installation service we provided.