Does the production of foam concrete block equipment affect the environment?

Does the production of foam concrete block equipment affect the environment?

The main raw materials used for foam concrete block equipment include fly ash, sand, stone powder, tailings, slag, construction waste, and cement. The production process consumes minimal water and electricity, with no discharge of wastewater, waste gas, or waste residue, meeting green industry production standards.

What should be paid attention to in the use of foam concrete machine?

What should be paid attention to in the use of foam concrete machine?

Foam concrete must be thoroughly mixed evenly with the foaming agent. Water usage must be strictly controlled, and only tap water should be used. Water containing acidic substances should not be mixed with the foaming agent to avoid chemical reactions that could affect the foaming agent's effectiveness.

How to pack foam concrete equipment before shipment?

How to pack foam concrete equipment before shipment?

Before delivery to the local shipping company, foam concrete machines and other goods are wrapped with packing tape. The packaged foam concrete machine is transferred to the local shipping company's dock for further preparation before shipping.

How to make foam concrete block smoothly?

How to make foam concrete block smoothly?

Pour cement, mineral powder, and an appropriate amount of water into a concrete mixer and mix evenly. Add the foaming agent and chemical additives into the mixer and mix again. Pour the mixed material into molds and compact it with an electric compactor. Once the material is fully solidified, use an electric concrete cutter to cut it into the desired size and shape. The foam concrete blocks can be used after they are fully dried.

How about the productivity of foam concrete machine?

How about the productivity of foam concrete machine?

Productivity is a key attribute of foam concrete machines. Modern high-speed pneumatic mixers have higher production rates per shift compared to machines using foam generators, as they save time on foam preparation and filling. Large-scale production lines can produce 100-1000 cubic meters of blocks per day.

Maintenance methods of foam concrete block equipment?

Maintenance methods of foam concrete block equipment?

Before transferring the machine to another site, maintenance should be performed, including checking internal and external components and applying anti-corrosion and rust prevention measures. Select appropriate lubricants and fuels for the season, and take anti-freeze measures in winter.

How can foam concrete equipment cool down in summer?

How can foam concrete equipment cool down in summer?

Before starting the machine each day, wet the molds with water to keep them moist and reduce heat generated by friction. After running for several hours, the machine should be stopped for about 20 minutes to prevent the motor from overheating. Regularly add lubricating oil to ensure smooth operation.

What is the technological process of ceramsite foam concrete block equipment?

What is the technological process of ceramsite foam concrete block equipment?

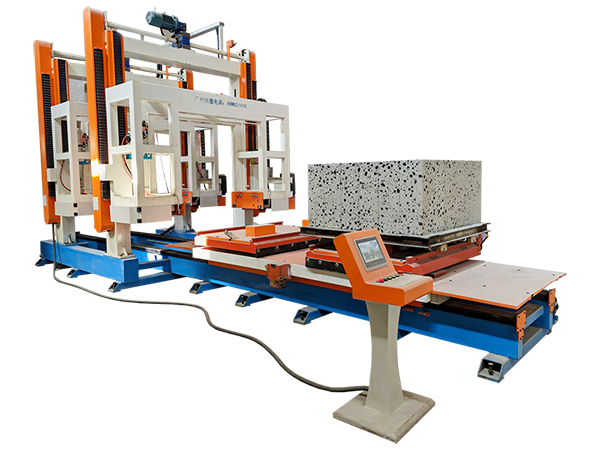

According to certain measurement requirements, add water, cement, and ceramsite, along with fly ash, stone powder, mineral powder, slag, or coal gangue (choose one), into the mixer. Mix for 5-10 minutes, then pour into molds. Once the material reaches demolding hardness, demould it, then cut it into blocks using a cutting machine. Finally, stack the finished concrete products using an automatic stacking machine.

What are the advantages of ceramsite foam concrete block equipment?

What are the advantages of ceramsite foam concrete block equipment?

The concrete block production line requires low investment, has low production and operational costs, and saves energy. It does not require traditional autoclaving, significantly saving electricity and coal. The automated control system ensures an environmentally friendly, pollution-free production process.

What should be paid attention to when starting to produce ceramsite foam concrete blocks?

What should be paid attention to when starting to produce ceramsite foam concrete blocks?

When starting production, you need to produce a foam concrete mixture that meets your country's standards at the lowest cost.

What is the effect of foaming agent content on the performance of ceramsite foam concrete?

What is the effect of foaming agent content on the performance of ceramsite foam concrete?

As the foam content increases, the strength and apparent density of ceramsite foam concrete decrease, while water absorption increases. When the foam content reaches 300%, the product strength can reach 1.12MPa, meeting the requirements for non-load-bearing walls.

What is a non autoclaved aerated block?

What is a non autoclaved aerated block?

Foam concrete blocks rely on natural curing of cement to achieve strength without the need for heating or autoclaving, hence they are called non-autoclaved aerated blocks (NAAC). This production method uses foam concrete to produce building blocks.

How is the heating block equipment insulated?

How is the heating block equipment insulated?

By adding chemical foaming agents to the concrete, certain sized pores and bubbles are formed during the curing process, creating a hollow structure. This structure provides excellent thermal insulation, effectively preventing heat transfer.

What are the characteristics of polystyrene foam concrete blocks?

What are the characteristics of polystyrene foam concrete blocks?

EPS foamed concrete is lighter and easier to work with, reducing the weight of buildings and improving overall performance. Its excellent thermal insulation ensures that buildings remain warm in winter and cool in summer. It also has good seismic performance, enhancing building safety.

What is polystyrene foam concrete block used for?

What is polystyrene foam concrete block used for?

It is widely used for thermal insulation layers in walls, floors, and roofs. It can also be used in road engineering to reduce vehicle load on road surfaces. Additionally, it is an environmentally friendly material that can be reprocessed or remelted into new products.

What is the workflow of polystyrene foam concrete cutter?

What is the workflow of polystyrene foam concrete cutter?

The foaming agent is evenly foamed in the storage tank and mixed thoroughly with various materials, additives, and water to form a foamed concrete slurry. This slurry is then poured into moulds through the discharge port of the mixing device. The moulds are sequentially transferred to a temperature control room, demoulding device, horizontal cutting device, and vertical cutting device.

What raw materials are needed for polystyrene foam concrete cutter?

What raw materials are needed for polystyrene foam concrete cutter?

- Cement: 425R Portland cement (required);

- EPS particles (required);

- Fly ash (optional);

- Fine stone powder (optional);

- Fine sand (mud content ≤5%, optional);

- Fine slag powder (optional);

- Additives (provided by the company).

What is the function of homogeneous insulation board equipment?

What is the function of homogeneous insulation board equipment?

Homogeneous insulation board equipment has a certain level of technical complexity and requires professional operation and maintenance. It uses ribbon blending and an automated operation system to ensure that raw materials are fully mixed. The resulting blocks have high density, a smooth appearance, and other beneficial properties.